Toll Free: (866) 215-0651

Local: (657) 900-2066

Industrial Manufacturing: Future-Proofing with Disruptive Tech

The world is changing at lightning speed—it's almost impossible to keep up! But don't worry; APS Industrial Services is here to help you navigate this ever-evolving landscape. In industrial manufacturing, staying ahead means embracing disruptive technologies. Future-proofing projects involve adapting to these innovations to ensure competitiveness and sustainability. Let's explore how industrial manufacturers can effectively navigate this technological shift.

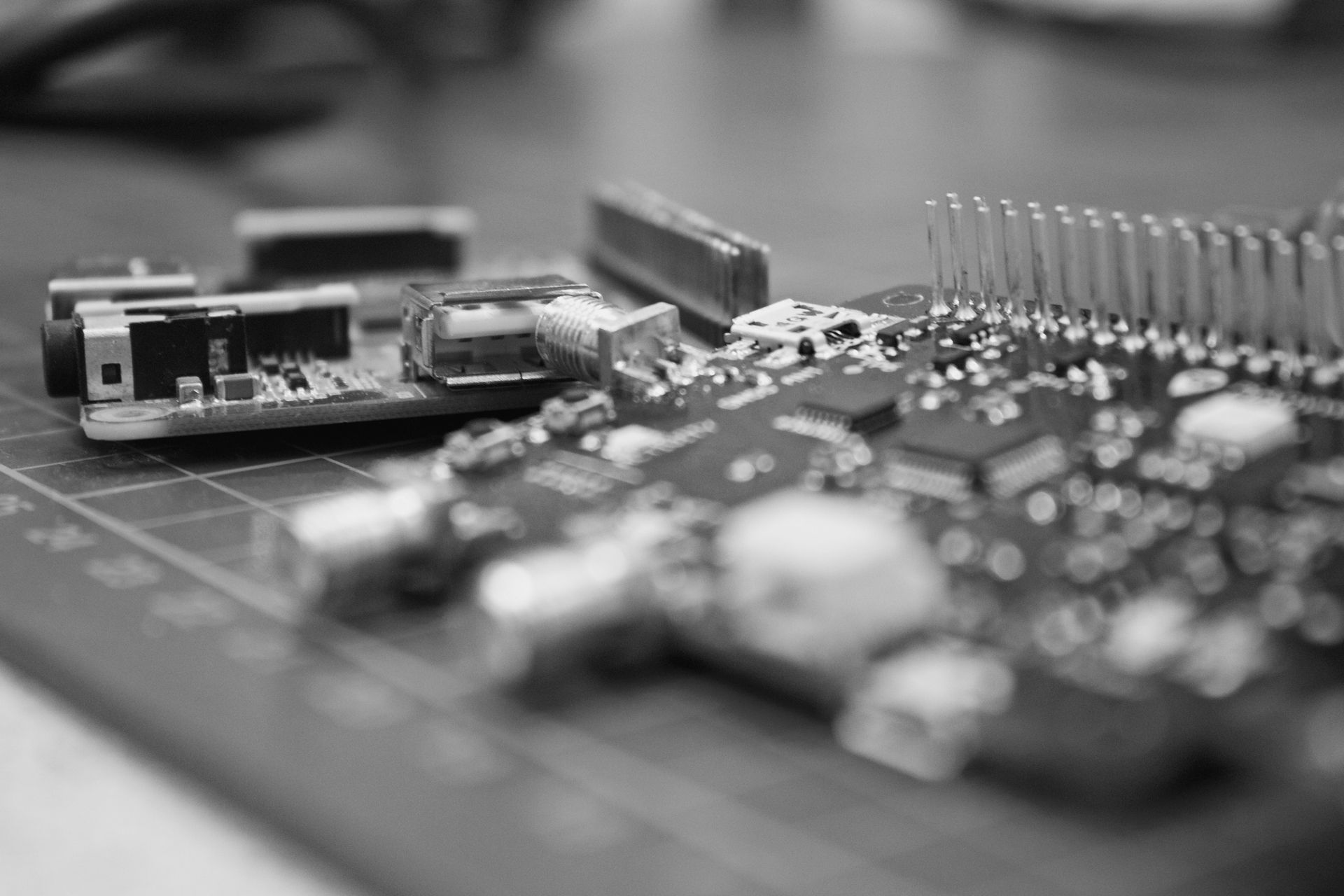

Embracing Industry 4.0:

Industry 4.0, characterized by integrating automation, data exchange, and IoT (Internet of Things), is revolutionizing industrial manufacturing. Embrace AI, machine learning, robotics, additive manufacturing, and digital twins to optimize processes, enhance productivity, and enable predictive maintenance. These technologies allow real-time monitoring, analysis, and optimization of manufacturing operations, leading to increased efficiency and reduced downtime.

Agile Project Management:

Implement agile methodologies to respond swiftly to technological advancements and market demands. Agile project management fosters flexibility, collaboration, and iterative development, enabling rapid adaptation to disruptive technologies. Break down projects into smaller, manageable tasks, prioritize customer feedback, and encourage cross-functional teams to collaborate closely. This approach allows quick adjustments to project scope, requirements, and deliverables, ensuring alignment with evolving technological trends and customer needs.

Investing in Talent Development:

Develop a skilled workforce capable of effectively leveraging emerging technologies. Invest in training programs, upskilling initiatives, and knowledge-sharing platforms to empower employees with the expertise needed to harness disruptive technologies for project success. Encourage a culture of lifelong learning, innovation, and experimentation within the organization. Provide opportunities for employees to gain hands-on experience with new technologies through workshops, hackathons, and collaborative projects.

Implementing Sustainable Practices:

Integrate sustainability into project planning and execution by leveraging eco-friendly technologies and practices. From energy-efficient manufacturing processes to waste reduction strategies, prioritize sustainability to future-proof projects and align with evolving environmental regulations. Embrace circular economy principles by designing products for reuse, recycling, and remanufacturing. Explore renewable energy sources like solar and wind power to reduce carbon emissions and minimize environmental impact throughout the manufacturing lifecycle.

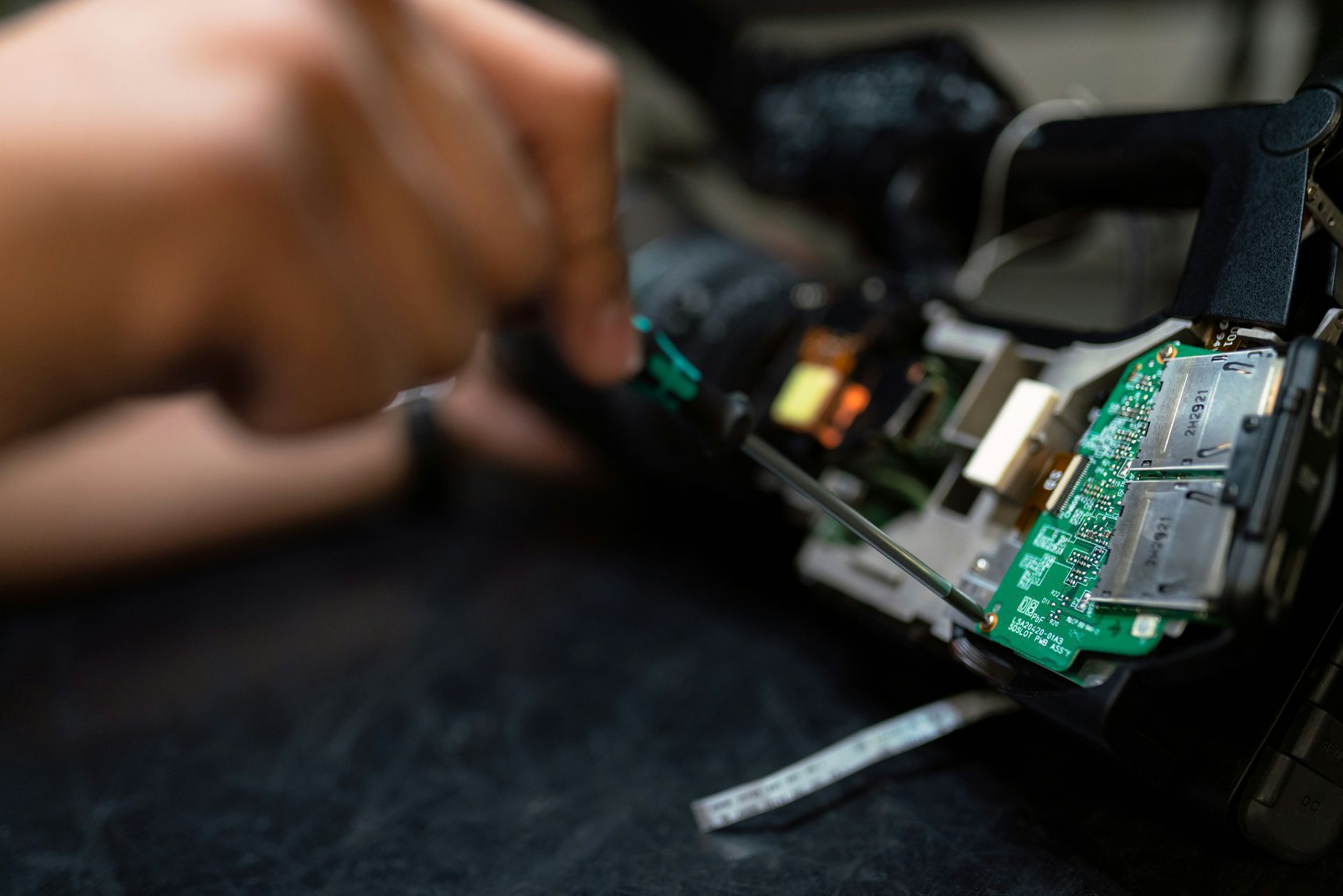

Collaborating with Tech Partners:

Forge strategic partnerships with technology providers and startups to access cutting-edge solutions and expertise. Collaborative innovation enables industrial manufacturers to leverage external resources and stay at the forefront of technological advancements—partner with research institutions, universities, and industry consortia to co-create innovative solutions and explore emerging technologies. Jointly invest in R&D initiatives and pilot projects to test and validate new technologies before scaling up implementation.

Continuous Evaluation and Adaptation:

Regularly assess project objectives, performance metrics, and technological trends to identify opportunities for improvement and adaptation. Embrace a culture of continuous evaluation and learning to stay agile and responsive in the face of disruptive technologies. Solicit stakeholder feedback, monitor key performance indicators, and benchmark against industry best practices—iterate project strategies based on insights gained from data analysis and market feedback. Embrace failure as a learning opportunity and encourage experimentation to drive innovation and continuous improvement.

Future-proofing projects in industrial manufacturing require a proactive approach to embracing disruptive technologies. By embracing Industry 4.0, adopting agile project management methodologies, investing in talent development, implementing sustainable practices, collaborating with tech partners, and continuously evaluating and adapting strategies, manufacturers can position themselves for long-term success in an ever-evolving landscape. Embrace the future today to thrive tomorrow.

Share On: