Toll Free: (866) 215-0651

Local: (657) 900-2066

Industrial IoT Revolution: Harnessing Data for Smarter Project Management

The Industrial Internet of Things (IIoT) has sparked a transformative revolution in project management within industrial sectors. This blog delves into the pivotal role of IIoT in revolutionizing project management practices by leveraging data analytics to enhance decision-making and optimize resource allocation.

Understanding the Industrial IoT:

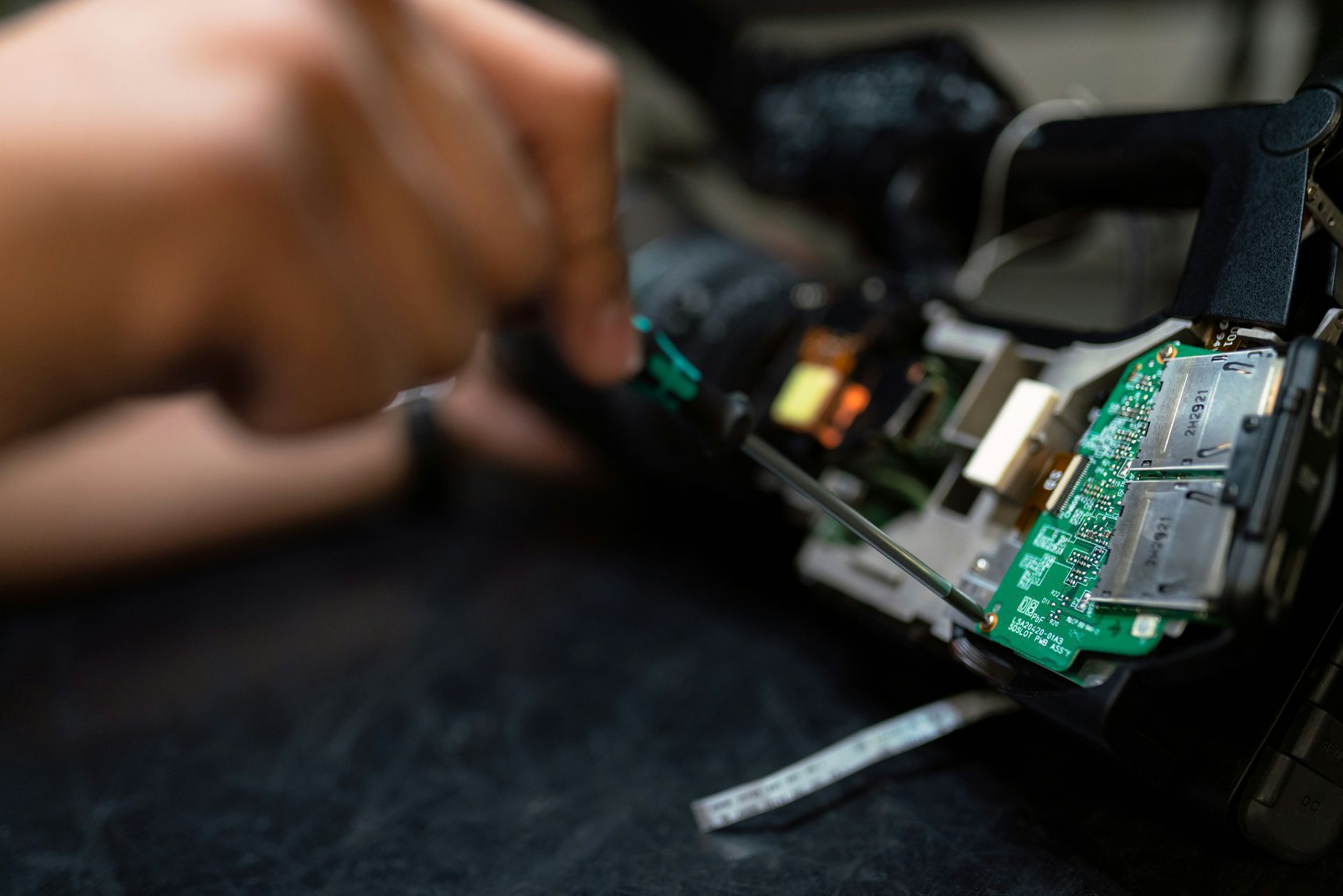

The Industrial IoT comprises interconnected devices, sensors, and machines embedded within industrial environments, facilitating real-time data collection and communication. This interconnected network empowers organizations to gather vast amounts of data from various sources, providing invaluable insights into operational efficiency, equipment performance, and overall productivity.

Transforming Project Management:

- Real-time Monitoring: IIoT enables continuous monitoring of key project parameters such as equipment status, energy consumption, and production metrics in real-time, allowing project managers to identify issues and mitigate risks proactively.

- Predictive Maintenance: By leveraging machine learning algorithms and predictive analytics, IIoT systems can anticipate equipment failures and schedule maintenance activities preemptively, minimizing downtime and optimizing asset utilization.

- Resource Optimization: Data-driven insights obtained from IIoT sensors enable precise resource allocation, optimizing workforce deployment, inventory management, and energy consumption, enhancing operational efficiency and cost-effectiveness.

- Enhanced Safety: IIoT-equipped devices provide valuable safety data, such as environmental conditions and worker location tracking, enabling proactive safety measures and rapid response to emergencies, thereby ensuring a safer work environment.

- Decision Support: Advanced analytics and visualization tools integrated with IIoT platforms empower project managers with actionable insights, facilitating informed decision-making and strategic planning to drive project success.

Case Studies:

- Smart Manufacturing: IIoT implementation in manufacturing facilities enables real-time monitoring of production processes, predictive maintenance of machinery, and optimization of supply chain logistics, resulting in improved productivity and cost savings.

- Construction Industry: IIoT sensors embedded in construction equipment and materials enable remote monitoring of construction sites, progress tracking, and safety compliance, enhancing project efficiency and reducing construction delays.

- Energy Sector: IIoT applications in the energy industry enable monitoring of power generation, transmission, and distribution networks, optimizing energy utilization, reducing downtime, and improving grid reliability.

The Industrial IoT revolutionizes project management by leveraging real-time data analytics to drive efficiency, productivity, and safety across industrial sectors. By harnessing the power of IoT, organizations can make informed decisions, optimize resource allocation, and unlock new avenues for innovation, positioning themselves for sustainable growth and competitive advantage in the digital era.

Share On: