Toll Free: (866) 215-0651

Local: (657) 900-2066

How Is Heavy Machinery Moved?

Have you ever seen a piece of heavy machinery and wondered just how it got there and how it'll be moved when the project ends? Or maybe you're struggling to figure out how to move a piece of bulky equipment yourself. Whatever the case may be, it's good to know how to safely and properly move heavy machinery.

According to the National Park Service, the Cape Hatteras lighthouse, which weighs 4,830 tons, was successfully relocated 2,900 feet from its original location. Well-orchestrated machine rigging made that move possible. If a heavy and historic lighthouse can be safely relocated, then your own heavy machinery can be, too. Here's some helpful information for machine rigging that you should know.

Machinery and Specialized Tools

You absolutely cannot attempt machine rigging without the necessary tools and supplies. The right equipment ensures that the job is performed in a safe manner. Jacks and pulleys can help lift machinery, while skates and skids can help to actually transport it. Only qualified contractors should handle such equipment. This is why you should only hire a professional, licensed service for machine rigging.

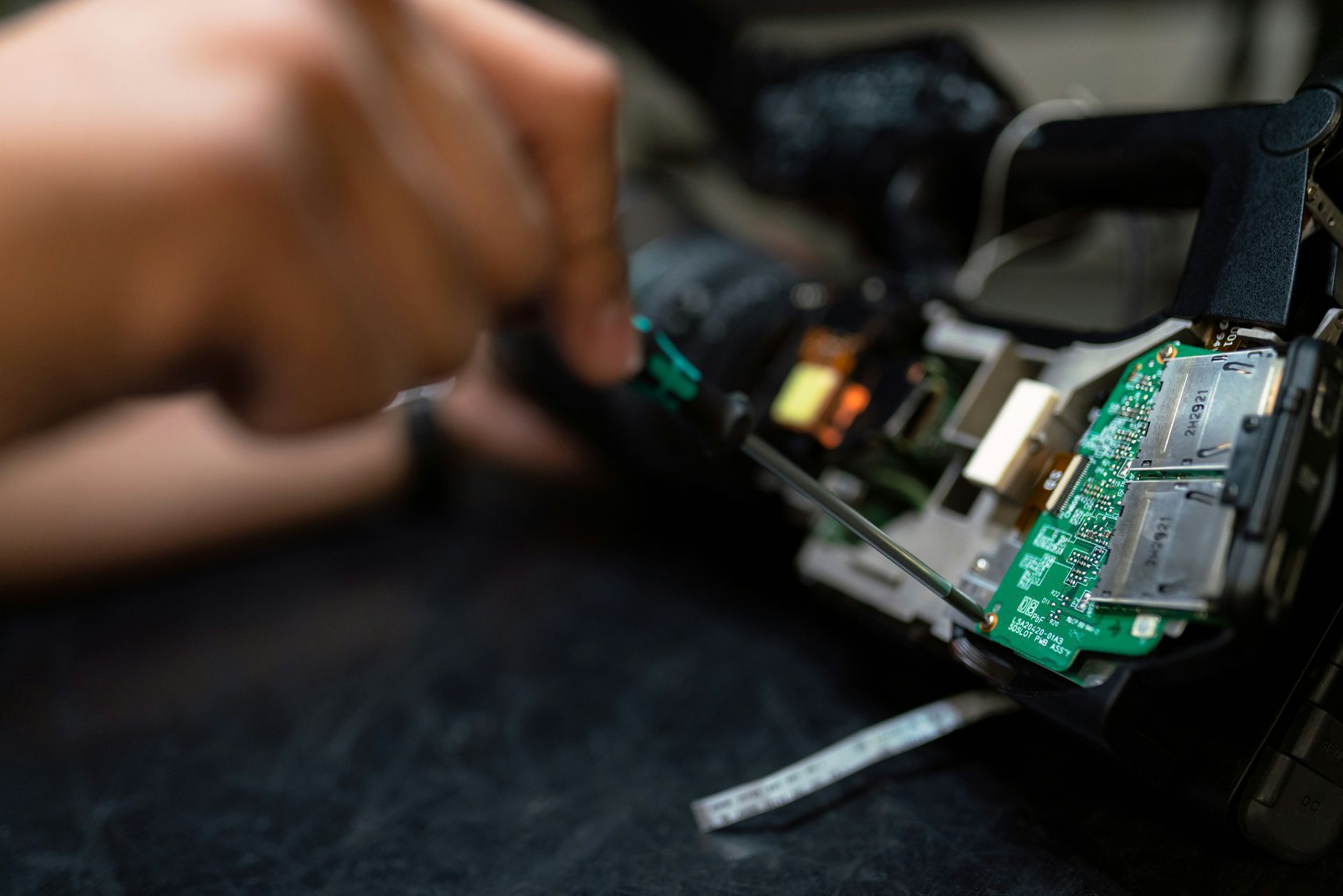

Disassembling and Reassembling

Heavy machinery can also be taken apart and moved piece by piece. Once all the pieces arrive at the destination, the machinery is reassembled. This option can be done very simply if the machinery can be disassembled into small and manageable pieces. If the pieces are too big or bulky, then pulleys or other equipment may be used.

Flatbeds and Trucks

A flatbed attached to a truck is a great way to transport machinery across a significant distance. The flatbed should have tie-downs that secure the equipment and make sure that it's moved safely from one point to the next. This option may also incorporate one or both of the methods outlined above. However, only a professional company can make this decision for you.

Heavy machine rigging requires serious considerations, so it's important to reach out to a professional before taking any steps. Reach out to APS Industrial Services today and allow us to help you.

Share On: