Facility Dismantling: A Deep Dive into Technical Processes and Equipment

In the world of industrial manufacturing, facilities often outlive their original purpose, paving the way for modernization, repurposing, or redevelopment. Facility dismantling is a highly technical process requiring precision, expertise, and specialized equipment. For business owners and facility managers, understanding the intricate science behind dismantling can aid in effective project planning, risk mitigation, and cost efficiency.

Step 1: Comprehensive Assessment and Planning

Every dismantling project begins with an in-depth assessment of the facility. This stage includes:

- Structural Analysis: Engineers analyze the building’s blueprints and structural integrity to determine safe dismantling methods.

- Material Identification: Identifying hazardous materials like asbestos, lead, or other contaminants ensures compliance with environmental regulations.

- Utility Shutdowns: Electrical, gas, and water lines are decommissioned to eliminate potential hazards.

A detailed project plan, outlining timelines, logistics, and safety measures, is then prepared to guide the dismantling process.

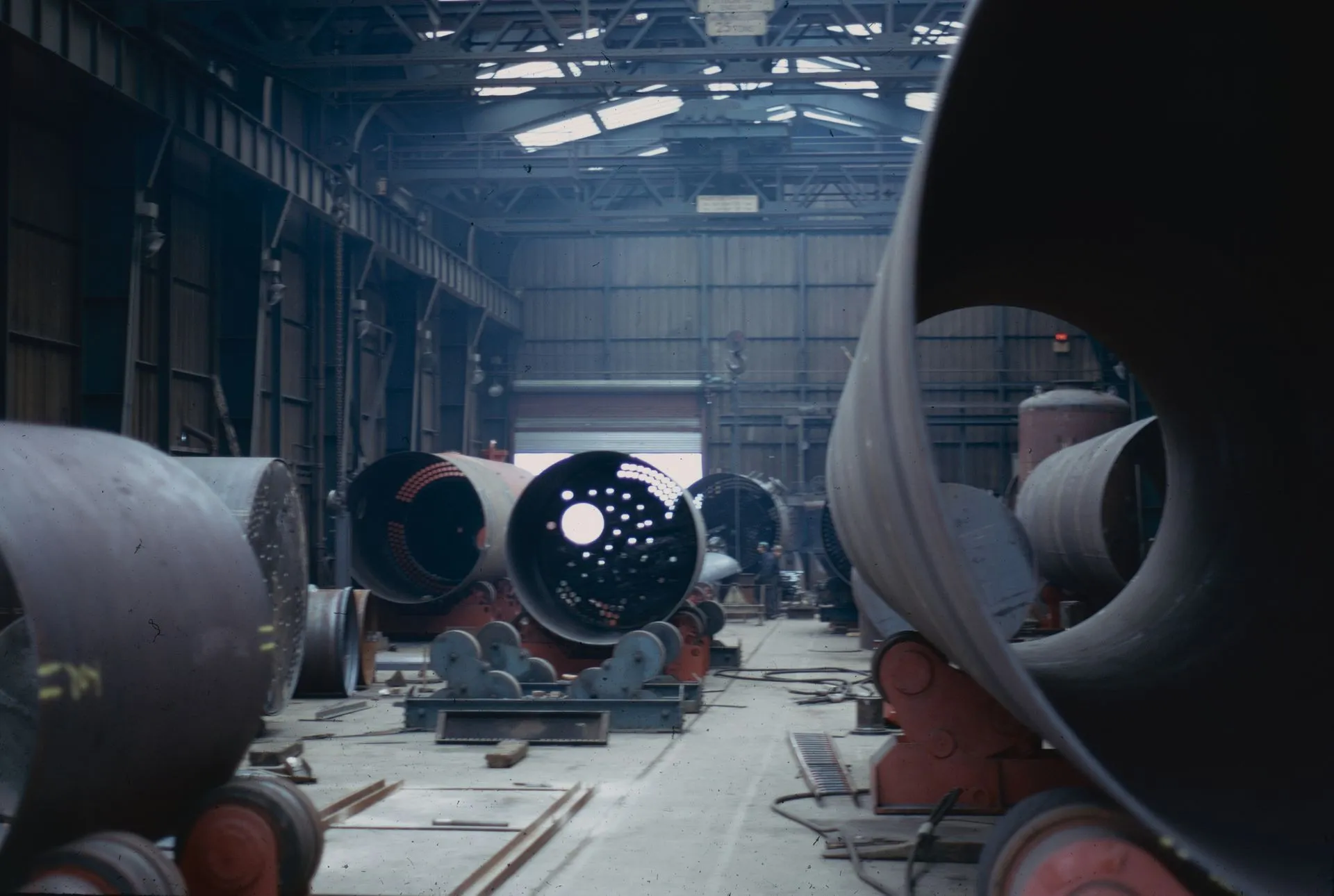

Step 2: Core Equipment for Facility Dismantling

The right tools are crucial for safe and efficient dismantling. Key equipment includes:

- Hydraulic Excavators: These machines are equipped with attachments like shears and grapples to tear down structural components.

- Cranes: Used for lifting heavy materials, particularly in multistory facilities.

- Diamond Wire Saws: Ideal for precise cuts through concrete and metal structures.

- Torch Cutters: Employed to cut steel beams and rebar into manageable sections.

- Debris Processing Equipment: Crushers and grinders break down concrete and other materials for recycling or disposal.

Step 3: Safety Protocols and Compliance

Safety is non-negotiable in facility dismantling. Strict adherence to OSHA and local regulations protects workers and surrounding communities. Critical measures include:

- Worker Safety Gear: Personal protective equipment (PPE) such as helmets, gloves, and respirators.

- Site Monitoring: Dust suppression systems, air quality monitors, and noise barriers reduce environmental impact.

- Emergency Preparedness: Contingency plans for unexpected events, such as structural collapses or hazardous material exposure.

Step 4: Environmental Considerations

Modern dismantling emphasizes sustainability. Materials such as steel, copper, and concrete are salvaged and recycled whenever possible. Proper disposal of hazardous materials prevents environmental contamination and aligns with regulatory guidelines

.

Step 5: Precision Execution

With plans and equipment in place, the dismantling begins. Controlled deconstruction techniques ensure safety and efficiency, whether by sectioning the facility into manageable zones or using explosive charges for large-scale demolitions. Close coordination between engineers, contractors, and equipment operators ensures each step proceeds as planned.

Why Facility Dismantling Matters

Dismantling a manufacturing facility isn’t just about tearing down walls—it’s about preparing for the future. From repurposing industrial land to creating opportunities for sustainable redevelopment, the dismantling process bridges the gap between the past and progress.

Final Thoughts

Facility dismantling is a precise and highly technical process requiring expertise and the right tools. For business owners and facility managers, understanding these steps and best practices ensures projects run smoothly, safely, and cost-effectively.

Newsletter

Don't miss a thing!

Sign up to receive daily news

Recent Posts

august 30, 2025

Decommissioning a Facility: How to Turn It into a Profitable Venture

august 25, 2025

Hydraulic Press Maintenance 101

august 18, 2025

Rigging Machinery: The Challenge of Moving and Installing Outdated vs. Modern Equipment

august 16, 2025

Conveyor System Maintenance: 5 Early Warning Signs of Failure

august 14, 2025

Predictive Maintenance: The Smarter Alternative to Costly Reactive Repairs

august 11, 2025